Product

Recommended article

- How Forestry Weather Stations Bolster Forest Fire Prevention Efforts

- Discover the Power of Negative Oxygen Ion Monitoring System for Cleaner Air

- Comparative Analysis of Ultrasonic and Automatic Weather Stations in Meteorological Monitoring

- Breaking Through the ‘Last Meter’ with Online Dust Monitoring System

- Mastering Road Conditions with Road Weather Station

- Inhalable Dust Continuous Tester: A Portable Solution for Dust Concentration Monitoring

Contact us

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

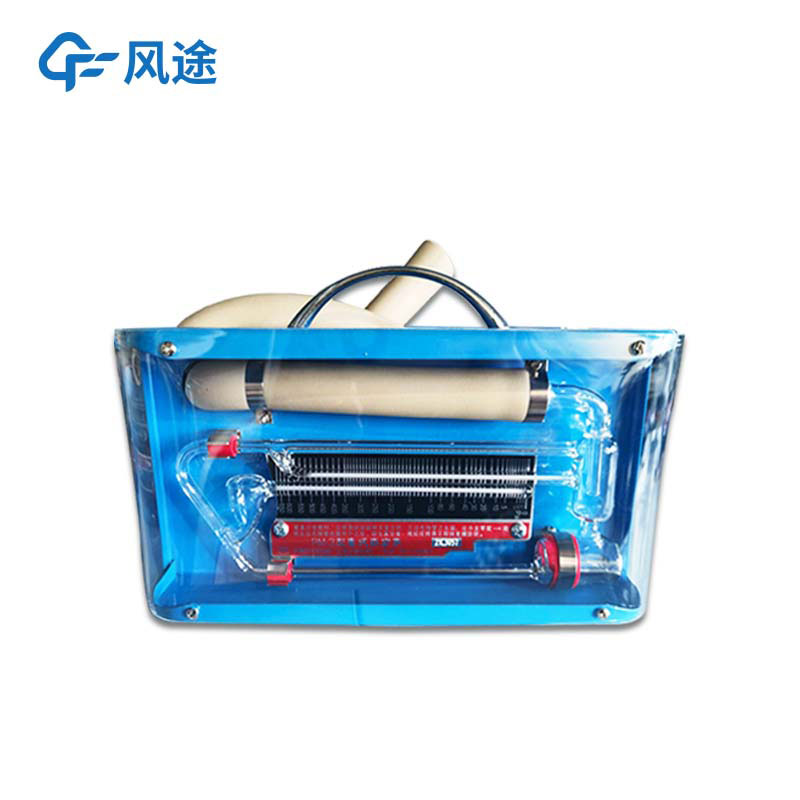

McLeod vacuum gauge

Model:PM-2

Brand:fengtu

Related products

1.McLeod vacuum gauge product introduction

McLeod vacuum gauge is an absolute vacuum gauge measuring pressure below 1Pa, proposed by McCraw, is the main instrument for calibrating other vacuum gauges.McLeod vacuum gauge, also known as McLeod vacuum gauge, fluid vacuum gauge, rotary compression vacuum gauge, measures the vacuum degree based on the Boyle-Mauriat law of ideal isothermal compression, so the measured value has an "absolute" meaning.

2. McLeod vacuum gauge product application

1.McLeod vacuum gauge is mainly used for measuring low vacuum in vacuum industrial production. It is widely used in central air-conditioning refrigeration units, metallurgy, magnesium smelting, petrochemical industry, vacuum furnaces, vacuum drying ovens, electronic tubes, high-voltage power equipment, medicine, scientific experiments, education research and metrology institutes, etc.

2. Because the McLeod vacuum gauge can directly calculate the pressure value through its own parameters, in addition to measuring pressure, it can also be used as an "absolute vacuum gauge" to calibrate some relative vacuum gauges, such as resistance vacuum gauges, thermocouple vacuum gauges and thin film vacuum gauges.

3. McLeod vacuum gauge technical parameters

| Specifications | Measuring range | Accuracy | Implementation standards or regulations | Dimensions |

| PM-2 | 0.1-650Pa-20KPa | Soil 20% | ZBY353-85Q/SSUPC01-2001 | 280x95x135mm(LxWxH) |

| PM-3 | 0.1-650Pa | Soil 20% | ||

| PM-4 | 0.1-650Pa | Soil 30% | 280x100x210mm(LxWxH) | |

| PM-3J | 0.1-1200Pa | Soil 8% | ||

| PM-4J | 0.1-1200Pa | Soil 10% |

4. McLeod vacuum gauge working environment conditions

Temperature -5~38℃, relative humidity ≤85%

5. McLeod vacuum gauge installation instructions

1. Before installation: Take the McLeod vacuum gauge out of the package and carefully observe the glass tube of the instrument. After making sure that it is not broken, cut off the nylon tie near the end of the vacuum hose, and then lift the vacuum hose vertically to allow the working medium (Hg) in the tube to flow back into the glass tube.

2. Installation: Remove the nylon tie at the end of the vacuum hose with the rubber plug, take out the rubber plug, apply vacuum grease on the inner port and connect it to the vacuum equipment to be tested. The connection must be welded with a vacuum valve to control the opening and closing of the pipeline. If necessary, put a tight ring on the interface and tighten the clamp to prevent air leakage.

3. Reading: Keep the meter in a horizontal state (handle upward) and operate the vacuum equipment for 1-3 minutes, then slowly open the vacuum valve and the meter enters the measuring state, and continue in the measuring state for 3-5 minutes (the duration varies depending on the size of the vacuum pump, so make your own judgment based on experience during the operation), and read the meter vertically. For specific operations, please refer to the printed instructions on the meter plate.

4. After the measurement: first restore the meter to a horizontal state (handle upwards), so that the measuring medium returns to the lower end of the glass tube, and then close the vacuum valve. If necessary, clamp the vacuum rubber hose with a clamp to isolate it from the vacuum system. This can ensure that the mercury in the vacuum gauge is clean and prevent the vacuum gauge from being broken by the strong impact of the atmosphere when the vacuum gauge is removed and separated; if the vacuum gauge is not removed, the valves of the mechanical pump and the vacuum system must be closed after the mechanical vacuum pump stops, and the mechanical pump should be released into the atmosphere to prevent the mechanical oil from returning to the vacuum system and the vacuum gauge from being contaminated by oil.

6. McLeod vacuum gauge maintenance and care

1. When transporting or using the Maxwell meter, it must be prevented from being inverted and lying flat to prevent mercury from flowing back into the vacuum core leather tube or mercury beads from entering the middle closed-tube capillary and blocking the capillary and affecting the measurement accuracy. Therefore, before each use, the vacuum core leather tube must be vertically turned upward to allow mercury to flow back into the vacuum meter glass tube.

2. During measurement, the vacuum gauge should be in an upright position. It is strictly forbidden to put any gas strongly into the vacuum system to avoid impacting the mercury in the glass tube and breaking the glass tube.

3. If the mercury beads accidentally enter the middle glass capillary (measuring closed tube) of the McLeod vacuum gauge during transportation or use and become stuck, a mechanical vacuum pump can be used to evacuate the McLeod vacuum gauge alone, and the vacuum gauge can be rotated back and forth to make the mercury stuck in the glass tube flow back into the mercury container.

4. The working medium (Hg) of the vacuum gauge has been specially treated and has a high degree of purity. Mercury oxidation contamination caused by long-term use will directly affect the measurement accuracy. It should be returned to the factory for repair and calibration in time and can only be used after passing the inspection.

Related article

-

Substation micrometeorological environment monitoring

2024-06-18 -

Introduction to the Integrated Forest and Grassland Fire Risk Factor Monitoring Station

2024-02-06 -

Enhancing Air Pollution Control with Grid-Based Regulation and High-Resolution Monitoring

2024-10-30 -

This is a small weather station that works well ......

2024-02-29 -

The Portable Meteorograph for Mobile Weather Tracking

2024-09-02 -

Discover the Power of Negative Oxygen Ion Monitoring System for Cleaner Air

2025-01-14 -

How does the Handheld Weather StationFT-SQ7B perform?

2024-08-14 -

Cellular Weather Station FT-SQ5: Embrace Precise Meteorological Monitoring

2024-09-29

Get a Free Quote

Get a Free Quote