Product

Recommended article

- How Forestry Weather Stations Bolster Forest Fire Prevention Efforts

- Discover the Power of Negative Oxygen Ion Monitoring System for Cleaner Air

- Comparative Analysis of Ultrasonic and Automatic Weather Stations in Meteorological Monitoring

- Breaking Through the ‘Last Meter’ with Online Dust Monitoring System

- Mastering Road Conditions with Road Weather Station

- Inhalable Dust Continuous Tester: A Portable Solution for Dust Concentration Monitoring

Contact us

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Photovoltaic panel hidden crack rapid detection instrument

Model:FT-EL3

Brand:fengtu

Related products

Photovoltaic panel hidden crack rapid detection instrument Product Introduction:

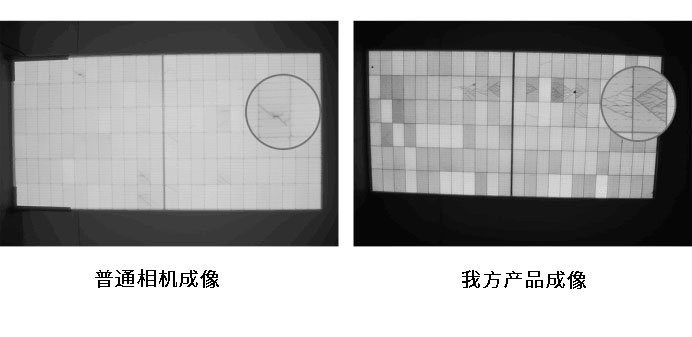

Photovoltaic panel hidden crack rapid detection instrument can detect surface and internal quality problems of photovoltaic panel components.Photovoltaic panel hidden crack rapid detection instrument is used for internal defect detection of photovoltaic solar panels, which can better help users complete product quality inspection and control production and installation risks.

Photovoltaic panel hidden crack rapid detection instrumentEL3 high-sensitivity detection equipment has higher imaging detection accuracy, which is more prominent in N-type half-cell module testing. It is also equipped with a larger capacity EL test power supply to help users meet the long-term detection needs of different module powers and power station scenarios.

EL3 also has multi-component imaging capabilities and can complete the synchronous imaging of 1 to 2 groups of photovoltaic panels. It has higher image quality and faster detection speed. It is the preferred equipment for photovoltaic power station detection business.

Photovoltaic panel hidden crack rapid detection instrument application scenarios:

EL3 is suitable for the inspection of photovoltaic power station components upon arrival and the testing of components on the bracket after installation, as well as the component quality inspection in warehouses/laboratories/factories. It can be equipped with string power supplies to realize multi-component string testing.

Identifiable defect types:

| Hidden crack | scrap | Fragments | Broken fence | Black Heart | Cold soldering | Hot Spot |

| Process pollution | Low efficiency film | Black border | sintering | Over-carved | perforation | pid |

Photovoltaic panel hidden crack rapid detection instrument product features and advantages:

1. 24 million high-sensitivity infrared camera, clearer image analysis

2. The full-time low-light autofocus module has better focusing performance in night tests

3. Networked wireless control equipment detection and detection data viewing and downloading

4. On-site testing of program-controlled constant current power supply realizes 24-hour uninterrupted testing

5. Tablet computer can wirelessly control equipment operation and view test results

6. On-site testing of large-capacity energy storage power supplies can be tested without any preparation

7. After the three-meter carbon fiber tripod is installed, multi-angle testing of components is more convenient

8. Wireless remote operation test of the whole machine, one person can complete the whole project

9. Triple-proof trolley case is light and safe to carry and transport

Photovoltaic panel hidden crack rapid detection instrument application areas:

| Scenes | Factory assembly, warehouse assembly, power station on-site assembly testing, string testing |

| test | During the day: outdoor infrared darkroom test; indoor test without sunlight; at night: direct tripod test, no effect from light or moonlight |

| Object | Crystalline silicon modules, thin film modules (customizable) |

| quantity | Monolithic component imaging inspection |

Photovoltaic panel hidden crack rapid detection instrument Optional accessories:

| String Camera | 45 million pixels, 1 to 24 modules string test |

| String power supply | 1500V imported program-controlled power supply, 1 to 36 components can be powered synchronously |

| Infrared proof darkroom | 2500x2500x1500mm daytime detection module |

| backup power | Output 60V10A, AC220V input, 1.5kg |

Photovoltaic panel hidden crack rapid detection instrument standard specifications:

| Modules | Configuration | Specification |

| Camera Module | Pixel | 24.76 million pixels (high sensitivity) |

| Resolution | 6000x4000 | |

| chip | 23.5x15.6mm, CMOS sensor | |

| Infrared chip | Lailx10s germanium chip 99.9% infrared refractive index | |

| Accuracy | 0.5.0mm/pixel | |

| Detection speed | 0.1~30s adjustable | |

| Weak current test | Can present clear crack imaging at 3A weak current | |

| Light Shielding | Lighting, moonlight, starlight, slight indoor sunlight, and sunlight below 300 irradiance have no effect on the test | |

| Detection area | 4000mm*3000mm | |

| Synchronous imaging | 1~2 components | |

| Lenses | 18mm wide angle infrared lens | |

| Focus Mode | Full-time low-light autofocus | |

| Battery | 980mah | |

| Memory card | 32GB | |

| Data cable | 10cm | |

| Power Module | capacity | 20AH |

| Batteries | High performance lithium battery | |

| Output current | 8A | |

| Current accuracy | 0.1A | |

| The output voltage | 70V | |

| Voltage accuracy | 0.1V | |

| Load power | 100W~700W; upper limit is not higher than 800W | |

| Number of tests | 800 to 1,000 photovoltaic panels | |

| control Panel | LED digital display program control panel | |

| Function settings | Delayed power off function | |

| Programmable module | Remote control wireless control detection power on | |

| Steady State Module | Constant power supply output current and voltage are not affected by changes in the amount of electricity | |

| Circuit Protection | Short circuit protection, open circuit protection, current backflow protection, overheat protection, static electricity protection, current and voltage adaptive matching photovoltaic panels | |

| On the wire | 10cm AC three-hole input line | |

| DC Line | 5m DC output cable, MC4 port docking assembly | |

| computer | tablet | 128G, 10.5 inches |

| Wi-Fi | 2.4G | Built-in 2.4G Wi-Fi wireless control module |

| 4G | High-performance Wi-Fi controller, 150 control range | |

| software | Detection Control | Wireless Control: Camera Detection |

| Camera Control | Adjustable camera exposure time, ISO, aperture, etc. | |

| Image Management | View original image, zoom in and out, compare albums, download | |

| Bracket system | Detection bracket | 2.6m carbon fiber bracket |

| Detection PTZ | 720 degree rotation | |

| Positioning module | Detection and positioning | Cross laser locator can quickly locate the position of the rear components on the bracket, which can improve the detection efficiency several times |

| Usage Environment | Desert, plateau, roof, hill, slope, factory, roof, snow, greenhouse, agricultural solar complementation, fish solar complementation, wind solar complementation, and other environments | |

| Warranty and after-sales service | 2-year warranty, 24-hour response, 72-hour fault resolution, spare parts coordination | |

Photovoltaic panel hidden crack rapid detection instrument configuration list:

| Serial number | name | EL3 Specifications | quantity | unit |

| 1 | EL Camera | 24 million infrared camera, full-time dark light auto focus, high-sensitivity infrared | 1 | tower |

| 2 | EL infrared lens | 18mm wide-angle infrared lens; accuracy 0.8mm | 1 | tower |

| 3 | tablet | 128G Tablet | 1 | tower |

| 4 | Wi-Fi transmission module | Built-in 2.4G Wi-Fi module | 1 | set |

| 5 | Wi-Fi Control Module | 4G Wi-Fi software control module; 150 meters wireless control | 1 | set |

| 6 | Data cable/charger | standard | 1 | set |

| 7 | Camera Batteries | standard | 2 | set |

| 8 | Detection bracket | 3m Carbon Fiber Tripod | 1 | set |

| 9 | Detection PTZ | 720 PTZ | 1 | tower |

| 10 | EL-DC Smart Power Bank | 20AH energy storage, 70V, 700W, constant current and constant voltage output, program control, battery life of 800-1000 components, wireless control on and off | 1 | tower |

| 11 | On the wire | 5 meters | 1 | root |

| 12 | Detection locator | Cross laser positioning, quickly locate and detect component positions | 1 | set |

| 13 | Equipment Trolley Case | Special triple-proof instrument trolley case; | 1 | set |

| 14 | LX-APP management software | IoT wireless detection, camera parameter adjustment; original image viewing, wireless detection, wireless image transmission, image download | 1 | set |

| 15 | Windows Software | Automatic detection, defect classification, identification and storage, folder date pipeline, statistics, gain, screenshot, camera parameter adjustment, professional management desktop software | 1 | set |

| * | Applicable scene | Photovoltaic power station pre-installation test; component test on the bracket |

Related article

-

Hardware configuration of forest fire risk factor monitoring stations

2024-08-06 -

"Highlights" of the integrated forest fire risk factor monitoring stations

2024-07-15 -

Principle of Light Scattering Dust Detector

2024-05-27 -

Digital weather stations in schools to foster scientific literacy among schoolchildren

2024-07-22 -

Forest fire weather station, intelligent fire prevention

2024-03-20 -

Discover the Power of Negative Oxygen Ion Monitoring System for Cleaner Air

2025-01-14 -

Breaking Through the ‘Last Meter’ with Online Dust Monitoring System

2025-01-10 -

Integrated forest fire risk factor monitoring station component

2024-05-16

Get a Free Quote

Get a Free Quote