Product

Recommended article

- One - Stop Dust Monitoring Solution

- How Forestry Weather Stations Bolster Forest Fire Prevention Efforts

- Discover the Power of Negative Oxygen Ion Monitoring System for Cleaner Air

- Comparative Analysis of Ultrasonic and Automatic Weather Stations in Meteorological Monitoring

- Breaking Through the ‘Last Meter’ with Online Dust Monitoring System

- Mastering Road Conditions with Road Weather Station

Contact us

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Volatile Organic Compounds (VOC) Monitoring

Model:FT-V3

Brand:fengtu

Related products

1. Volatile Organic Compounds (VOC) Monitoring Product Overview

Volatile Organic Compounds (VOC) Monitoring can monitor the total hydrocarbon, non-methane hydrocarbon and methane in the ambient air in real time.

1.Background and application fields of Volatile Organic Compounds (VOC) Monitoring

Volatile organic compounds (VOCs) are important precursors to the formation of secondary pollutants such as fine particulate matter (PM2.5) and ozone (O₃), which in turn cause atmospheric environmental problems such as haze and photochemical smog.With the rapid development of industrialization and urbanization in my country and the continuous growth of energy consumption, the frequency of large-scale simultaneous occurrence of severe air pollution in the region is increasing, which seriously restricts the sustainable development of the social economy and threatens the health of the people.Therefore, in order to fundamentally solve the pollution problems such as PM2.5 and O₃ and effectively improve the quality of the atmospheric environment, the country actively promotes the pollution prevention and control of its key precursor VOCs.In recent years, Beijing-Tianjin-Hebei and surrounding provinces and cities have strengthened the online monitoring of volatile organic compound emissions from key industrial sources, and put forward clear construction requirements for the installation and networking of fixed pollution sources of volatile organic compounds (VOCs) in key industries, online monitoring facilities for unorganized emissions, and excessive alarm sensor devices.

VOCs emission monitoring mainly involves industries such as petrochemicals, organic chemicals, pharmaceutical manufacturing, industrial coatings, machinery manufacturing, packaging and printing, electronic production, synthetic leather, coatings and paints, clothing processing, furniture manufacturing, adhesives, shoemaking, and oil storage and transportation.At the same time, the emission has the characteristics of unorganized fugitives and organized fixed pollution sources, many types of pollutants, large concentration changes, and uncertain emission time.The TVOC automatic monitoring and alarm system can provide real-time contact and provide data on the total amount of TVOC and key monitoring factors of various industries, and connect with the competent departments of the Environmental Protection Bureau online in real time to realize the functions of real-time monitoring of the total amount of TVOC emission reduction and pollution discharge fees.

2.Volatile Organic Compounds (VOC) Monitoring Scope

The monitoring factors of this product are benzene, toluene, xylene, styrene, trichloroethylene, chloroform, trichloroethane, diisocyanate (TDI), etc.

The product is based on the "Technical Requirements and Detection Methods for Continuous Monitoring System of Volatile Organic Compounds in Ambient Air by Gas Chromatography" (HJ 1010-2018)

"Notice on Strengthening the Monitoring of Volatile Organic Compounds in Waste Gas from Stationary Pollution Sources"

《Gas chromatography method for determination of total hydrocarbons, methane and non-methane hydrocarbons in waste gas from stationary pollution sources》

Online monitoring of TVOC organized emissions, total organic matter analysis, unorganized emissions, and online monitoring of TVOC flue gas and exhaust gas;

Total organic matter analysis in online monitoring before/after TVOC recovery and finishing;

Flue gas monitoring in the combustion control room of circulating fluidized bed boilers in thermal power plants;

Steel mill heating furnace is used to detect furnace gas atmosphere when reducing oxidation loss or decarburization layer thickness;

The full hydrogen heat treatment furnace is used to detect whether the radiation tube is burned through and leaking; automobile exhaust emission detection;

Other industrial kilns and waste incinerators exhaust gas monitoring.Industrial emission of volatile organic waste gas;

Quantitative and qualitative analysis of total hydrocarbons (THC) and non-methane hydrocarbons (NMHX), benzene, dimethylformamide, alkanes, alkenes and cyclic aromatic hydrocarbons in the emission pipeline;

Complex toxic and hazardous organic substances in industrial or chemical areas;

Online monitoring of VOC pollution sources;

Online monitoring of odorous organic sulfides;

Online monitoring of multi-point fugitive emissions at factory boundaries

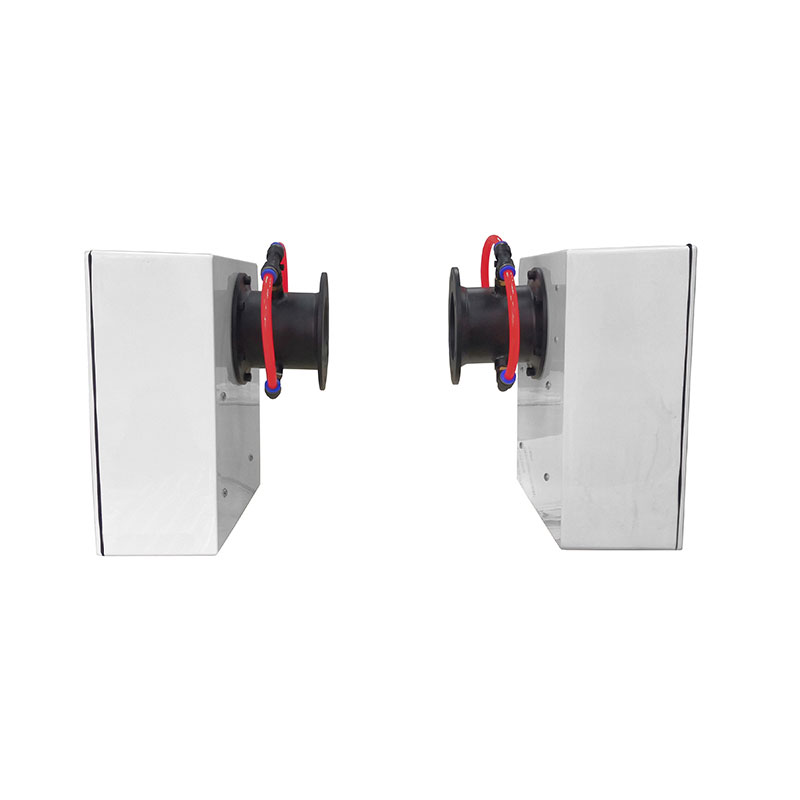

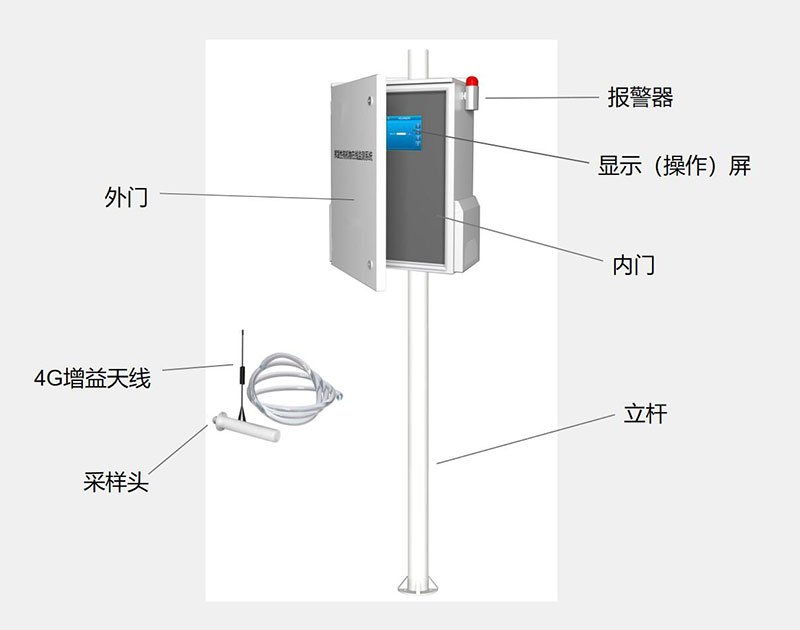

3.Volatile Organic Compounds (VOC) Monitoring Structure Composition

4.Volatile Organic Compounds (VOC) Monitoring Principle

Electrochemical, Organized

2.Features of Volatile Organic Compounds (VOC) Monitoring

1.High-performance sensor with good anti-interference performance, stable and reliable pre-processing unit, and diaphragm pump technology.

2.The LCD panel display adopts a 7" touch screen display, full Chinese interface, and human-computer interaction interface for easy operation.Intuitive display of working data.

3.Wireless 4G network transmits data, the transmission is stable and reliable, and the full software automatic calibration function.

4.Support backflush function.The detection site has an on-site sound and light alarm function, and an immediate alarm will be issued when the gas concentration exceeds the standard, which is a safety guarantee for dangerous on-site operations.

5.Independent air chamber, no on-site calibration is required when replacing the sensor, and the key parameters of the sensor are automatically identified.

6.Adopting microprocessor technology, fast response speed, high measurement accuracy, good stability and repeatability

7.The detection site has an on-site sound and light alarm function, and an immediate alarm will be given when the gas concentration exceeds the standard, which is a safety guarantee for dangerous on-site operations

8.On-site large-screen multi-parameter LCD display with backlight, intuitively displays gas concentration, type, unit, working status, etc.

9.Independent air chamber, no on-site calibration required for sensor replacement, automatic identification of key sensor parameters

10.Full range temperature digital automatic tracking compensation to ensure measurement accuracy

3.Volatile Organic Compounds (VOC) Monitoring Product Parameters

| Display unit | Display parameters | 7" true color LCD screen (800×480) |

| How it works | Touch Operation | |

| Transmission standards | Data Protocol | Data transmission standard for online automatic monitoring (surveillance) system of pollution sources (HJ212-2005) |

| Communication interface | Sensor interface | RS485/Modbus |

| Switching interface | 2-way | |

| Data Communications | 4G wireless transmission, 1min upload interval | |

| Work Environment | temperature | -25℃~+70℃ |

| humidity | 5%RH~95%RH | |

| System Parameters | power supply | AC220V±10% 50Hz |

| Power consumption | ≤15W | |

| Electromagnetic compatibility | IEC Level 3 | |

| TVOCs probe | Measuring principle | PID |

| Sampling method | Pump suction type (2L/min) | |

| Range | 0~20ppm,100ppm,1000ppm | |

| Temperature and humidity | -20~70℃;0~~100%RH | |

| Indication error | ≤10%FS | |

| Zero drift | 1H zero drift ≤5%FS 24H zero drift ≤20%FS | |

| Range drift | 1H range drift ≤5%FS 24H range drift ≤20%FS | |

| Response time | <120s | |

| Repeatability | ≤5% | |

| Measurement error | ≤20% |

4.Volatile Organic Compounds (VOC) Monitoring Cloud Platform

1.Perfect docking capability with government regulatory platforms

2.Multi-tasking, high concurrency, low latency

3.Multi-platform simultaneous viewing and multi-dimensional retrieval capabilities

4.Data highlight alarm and SMS push capabilities

5.Multi-level management and authority allocation capabilities

6.Support large-screen data display and customized development

Related article

-

What are the four conditions of agricultural monitoring?

2024-02-26 -

How Landslide Monitoring Systems Work to Mitigate Geological Hazards

2024-12-04 -

Portable Weather Station "Highlights"

2024-01-31 -

Road Weather Information System: Tackling the Challenge of Dense Fog Patches

2024-09-30 -

Substation micrometeorological environment monitoring

2024-06-18 -

Negative Oxygen Ion Monitoring System Builds Scenic Image

2024-04-16 -

The Prominent Role of Fengtu's Road Weather Station in Transportation

2024-11-19 -

Meteorological equipment for disaster prevention and mitigation

2024-03-01

Get a Free Quote

Get a Free Quote