Product

Recommended article

- Taming Dust Pollution with the Dust Monitoring System

- The All - in - One Grassland Ecological Monitoring Station (FT - CQX9)

- Combatting Dust Pollution: The Pivotal Role of Cruise Monitoring System

- On - the - Go Meteorology: Unraveling the Power of Vehicle - Mount Weather Stations

- The Crucial Link: Photovoltaic Weather Station and Efficient PV Generation

- Monitoring Forest Litter Moisture Content

Contact us

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

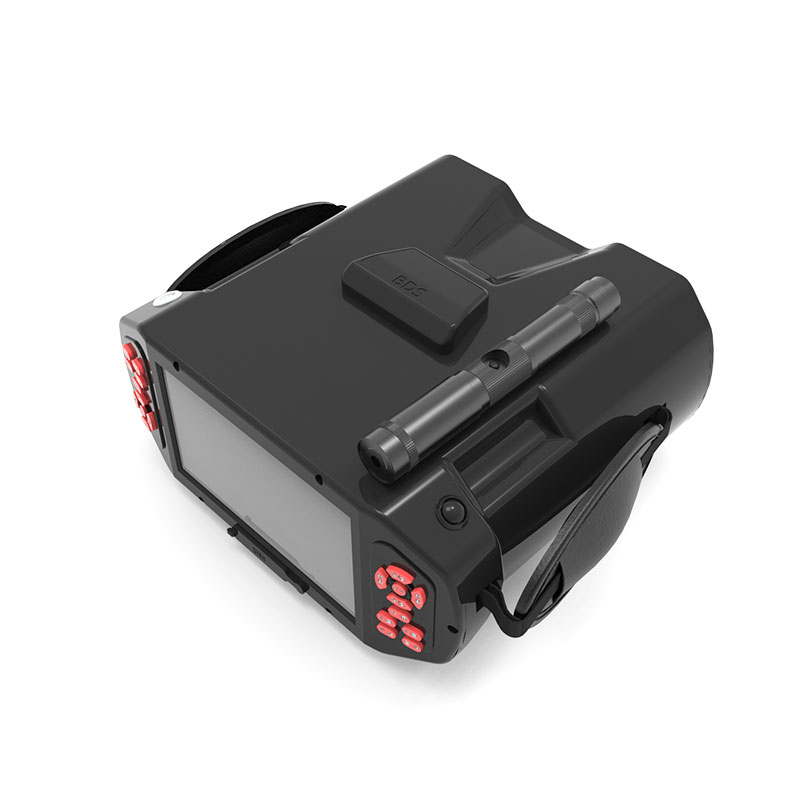

Automatic Test DC Power Supply

Model:FT-150010

Brand:fengtu

Related products

1.Automatic Test DC Power Supply Product Introduction

Automatic Test DC Power Supply The internal defect test of EL is carried out for converting AC to DC power input panel to excite electroluminescence.

FT-150010 is a research and development type program-controlled power supply, which controls the electrical performance and safeguards of Automatic Test DC Power Supply through the program software system. Its pro version is a high-quality software configuration, using higher-quality imported electronic components with an open programming host, which can better ensure the stability and safety of string detection.

2. Automatic Test DC Power Supply Technical Parameters

1. ELAutomatic Test DC Power Supply for Photovoltaic

| Specification | FT-150030 | FT-150050 | FT-150010 |

| Power parameters | 0~1500V; 0~3A | 0~1500V; 0~5A | 0~1500V; 0~10A |

| quality | Programmable linear domestic | Program-controlled custom import | Program-controlled custom import |

| Scenes | EL detector single block/string test | EL detector single block/string test | EL detector + drone EL test |

| Voltage output | 0~1500V | 0~1500V | 0~1500V |

| Voltage accuracy | 1V | 0.001V | 0.001V |

| Compensation voltage | 12V | 96V | 96V |

| Current output | 0~3A | 0~5A | 0~10A |

| Current accuracy | 0.1A | 0.001A | 0.001A |

| Power accuracy | ±0.1A; ±1V | ±0.001A; ±0.001V | ±0.001A; ±0.001V |

| Power Output | 0~4.5KW | 0~8KW | 0~16KW |

| Power stability | ±0.1% | ±0.002% | ±0.002% |

| Output accuracy | ±0.1% | ±0.001% | ±0.001% |

| Output efficiency | >80% | >95% | >95% |

| Output Line Regulation | ±0.5% | ±0.005% | ±0.005% |

| Output load regulation | ±0.5% | ±0.005% | ±0.005% |

| Input voltage | 220VAC | 380VAC | 380VAC |

| Input frequency | 50/60Hz | 50/80Hz | 50/100Hz |

| Input Power Factor | >0.75 | >0.5 | >0.5 |

| Power-on time | Manual control | Program-controlled timing automatic power on and power off | |

| Insulation withstand voltage input to output | 2500VDC | ||

| Insulation withstand voltage output to shell | 500VDC | ||

| OVP adjustment range | 0-100% front panel adjustment (or digital interface) | ||

| OVP regulation accuracy | ±1% rated value | ||

2. ELAutomatic Test DC Power Supply/Programmable Control System

| Specification | FT-150030 | FT-150050 | FT-150010 |

| Programmable control system | Control current and voltage output and monitor power supply working status | The program control panel can directly set various program control indicators of the power supply | |

| Programmable remote interface | RS-485C, analog interface (0-10V) | ||

| Programmable control panel | - | The power panel can be programmed to control the power on and off time, timed power on, protection threshold, etc. | |

| Reverse current protection | - | The reverse current impedance threshold can be set to prevent string current backflow | |

| Short circuit protection | PV string reverse connection short circuit protection to prevent PV module diode breakdown | ||

| Program-controlled buffer protection | - | Cache-type photovoltaic groups are disconnected in series to prevent large currents from directly penetrating the photovoltaic panels | |

| Program-controlled steady-state output | - | Adaptively match current and voltage according to different power components in the string (avoid breakdown of component diodes) | |

| Digital voltage programming accuracy | - | ±0.001% | ±0.001% |

| Digital current programming accuracy | - | ±0.001% | ±0.001% |

| Programmable rise time | - | 0~10s can be set | |

| Programmable fall time | - | 60ms (no load); 250ms (load 10%); 2.5s (full load) | |

| Voltage fluctuation control | 0.1V/ms~10V/ms | 0.001V/ms~0.002V/ms | |

| Current fluctuation control | 0.1A~0.2A | 0.001A~0.01A, or 1NF | |

| Minimum time for fluctuation control | 5ms | 0.1ms | |

| Panel Display | Digital display insulation control panel | Host control panel | |

| Panel Control | - | The power supply current and voltage protection limit value OVP can be set | |

| Photovoltaic EL power-on characteristics | High and low current switching test (manual switching) | High and low current switching test (programmed automatic switching) | |

| Number of components powered on simultaneously | Can simultaneously complete the detection and power supply access of 1 to 32 photovoltaic panels (within 1500V) | ||

| Photovoltaic power access port | Combiner Box / Inverter / String Port / Module Port | ||

| Steady-state output module | - | Stable power-on: The power parameters of each component in the string are consistent on average (to prevent photovoltaic panel breakdown) | |

| Constant temperature control module | Air cooling for continuous heat dissipation and temperature control | Electronic temperature control at 45°C ensures 24-hour operation | |

| Overload protection | - | The overload threshold can be set, and the output will stop automatically when overloaded to prevent the power supply transformer from being burned. | |

| Output short circuit automatic protection | Protect against power failure and personal danger caused by power station line or component string disconnection, and the power supply is automatically cut off | ||

| Input voltage automatic protection | - | Can protect power supply components from burning out due to excessive input voltage fluctuations | |

| Phase loss protection | Can protect against power damage and accidents caused by three-phase circuit breaker | ||

| Internal overheat protection | Dynamically dissipate heat according to the internal temperature to ensure that the power supply will not burn out due to overheating | ||

| High voltage isolation protection | Ensure the safety of high voltage electrical work for operators of the whole machine casing and panel | ||

| Input Line | 2 meters (6 square meters) | ||

| Wiring | AC220 | Three-phase three-wire + ground wire | |

| volume and weight | 430x88x450mm; 13kg | 17kg | 26kg |

Note: Automatic Test DC Power Supply is a high-power DC output power supply, which is a high-voltage equipment. The program control system is customized for photovoltaic power station scenarios, which can better ensure the safety of on-site manual construction. However, high-voltage equipment is still a high-risk and high-risk equipment. Please strictly follow the operating instructions and standardize wiring and operation. In the event of power protection, contact the manufacturer as soon as possible to resolve the problem. Do not operate the wiring without authorization to prevent danger! ! !

Related article

-

Which IoT devices are suitable for weather stations?

2024-03-13 -

What is an on-farm microclimate monitoring system?

2024-05-15 -

Forestry Weather Station: Your All-in-One Fire Risk Sentinel in the Woods

2024-12-09 -

Features Galore: Key Advantages of Environmental Monitoring Station FT - FZ3

2024-10-12 -

Villagers Air quality monitoring station

2024-08-15 -

Dust Detector: Navigating the Challenges of dust pollution in construction

2024-12-26 -

Dust monitoring system for in-depth environmental protection

2024-02-20 -

Local Air Quality Soars as Dust detector Drives Effective Pollution Control

2024-12-06

Get a Free Quote

Get a Free Quote