Product

Recommended article

- One - Stop Dust Monitoring Solution

- How Forestry Weather Stations Bolster Forest Fire Prevention Efforts

- Discover the Power of Negative Oxygen Ion Monitoring System for Cleaner Air

- Comparative Analysis of Ultrasonic and Automatic Weather Stations in Meteorological Monitoring

- Breaking Through the ‘Last Meter’ with Online Dust Monitoring System

- Mastering Road Conditions with Road Weather Station

Contact us

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Explosion Proof Sensor

Model:FT-WFB5

Brand:fengtu

Related products

1.Explosion Proof Sensor Product Introduction

Explosion Proof Sensor is an instrument for environmental monitoring in flammable and explosive environments. It has explosion-proof performance and can work in dangerous environments.Shandong Fengtu Internet of Things Technology Co., Ltd., as a company specializing in the development, production and sales of integrated explosion-proof meteorological sensors, has been committed to the promotion and application of micro-meteorological instruments and meteorological environment solutions. With a complete production chain, a strong technical team and a comprehensive marketing team, the meteorological products we develop and produce, such as ultrasonic explosion-proof wind speed and direction instruments, explosion-proof five-element micro-meteorological instruments, have been widely used in chemical plants, oil depots, tunnels, mines and other fields, with customers all over the country, and have achieved good social and economic benefits.

Compared with traditional micro-meteorological instruments, our products overcome the need for high-precision timers and avoid inaccurate measurements caused by sensor startup delays, demodulation circuit delays, and temperature changes.

Explosion Proof Sensor innovatively realizes wind speed, wind direction, temperature, humidity and atmospheric pressure through a highly integrated structure, which can realize 24-hour continuous online monitoring of outdoor meteorological parameters and output the five parameters to the user at one time through the digital communication interface.

2. Explosion Proof Sensor Product Features

1. The top cover hides the ultrasonic probe to avoid interference from rain and snow accumulation and avoid being blocked by natural wind (utility model patent, patent number ZL 2020 2 3215713.X)☆

2. The principle is to emit a continuous frequency-variable ultrasonic signal and detect wind speed and direction by measuring the relative phase (invention patent, patent number ZL 2021 1 0237536.5)☆

3. Wind speed, wind direction, temperature, humidity and atmospheric pressure integrated (utility model patent, patent number ZL 2020 2 3215649.5)☆

4. Using advanced sensing technology, real-time measurement, no start-up wind speed☆

5. Strong anti-interference ability, with watchdog circuit and automatic reset function to ensure stable operation of the system

6. High integration, no moving parts, zero wear

7. Maintenance-free, no need for on-site calibration

8. ASA engineering plastics are used for outdoor applications without discoloration all year round.

9. The product design output signal is standardly equipped with RS485 communication interface (MODBUS protocol); 232, USB, Ethernet interface are optional, supporting real-time data reading☆

10. Optional wireless transmission module, minimum transmission interval 1 minute

11. The probe adopts a snap-on design, which solves the problem of looseness during transportation and installation.

3. Explosion Proof Sensor Technical Parameters

1. Wind speed: Measurement principle: ultrasonic, 0-60m/s (±0.1m/s), resolution: 0.01m/s; (invention patent, patent number: ZL 2021 1 0237536.5)

2. Wind direction: Measurement principle: ultrasonic, 0-360° (±2°); resolution: 1°; (invention patent, patent number ZL 2021 1 0237536.5)

3. Air temperature: Measurement principle: diode junction voltage method, -40-60℃ (±0.3℃), resolution 0.01℃; (Calibration certificate from Beijing Meteorological Bureau)

4. Air humidity: Measurement principle: capacitive, 0-100%RH (±3%RH), resolution: 0.1%RH; (Calibration certificate from Beijing Meteorological Bureau)

5. Atmospheric pressure: Measurement principle: piezoresistive, 300-1100hpa (±0.25%), resolution: 0.1hpa; (Calibration certificate from Beijing Meteorological Bureau)

6. The manufacturing enterprise has ISO quality management system, environmental management system and occupational health management system certification☆

7. The manufacturer has a computer software registration certificate☆

8. The manufacturer is a 3A credit enterprise☆

9. The manufacturer has Ex ia IIC T4 Ga high-level explosion-proof certificate☆

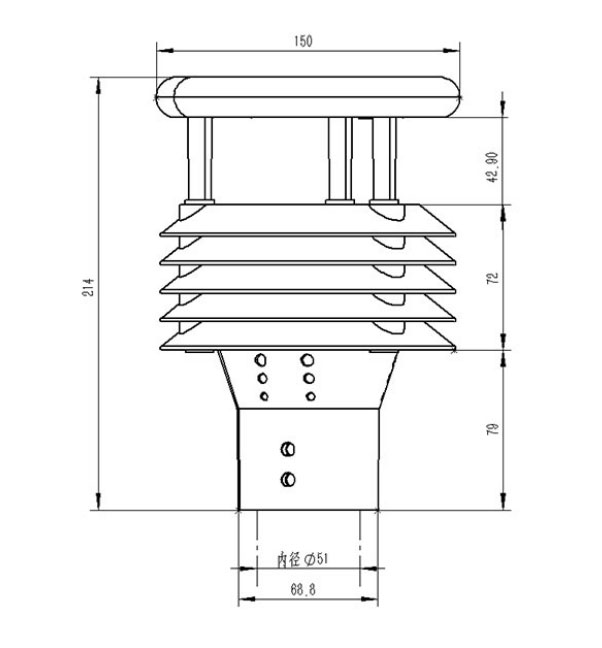

4. Explosion Proof Sensor Product Dimensions

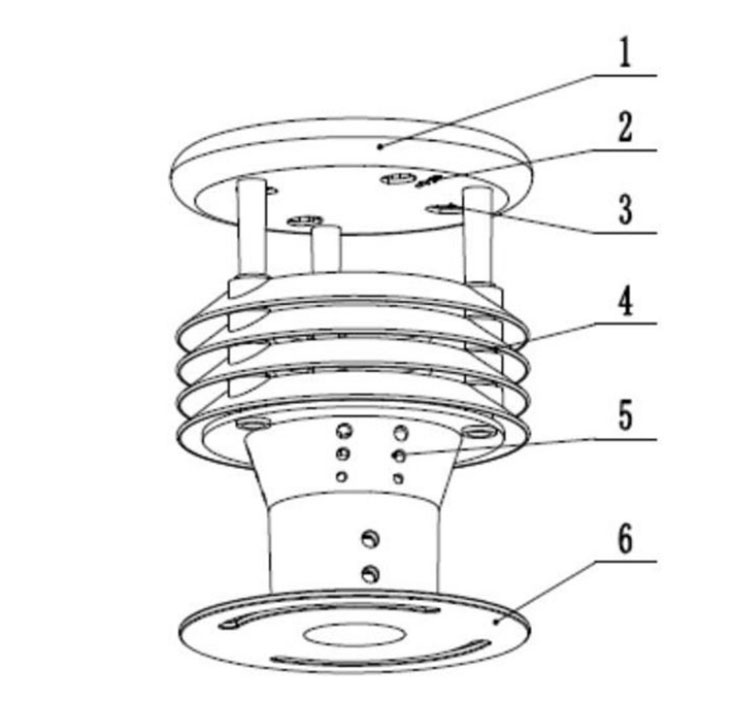

5. Explosion Proof Sensor Product Structure Diagram

1. Control circuit

2. North arrow

3. Ultrasonic probe

4. Shutter Box

5. Temperature, humidity and air pressure monitoring location

6. Bottom fixing flange

※This product can be equipped with electronic compass, GPRS (built-in)/GPS (choose one of the two)

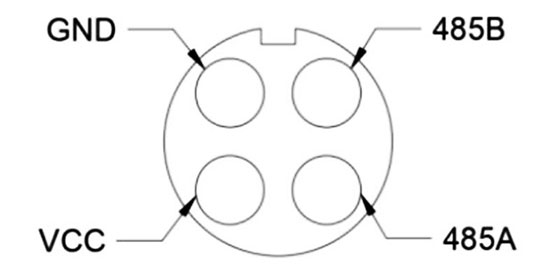

6. Explosion Proof Sensor Product Wiring Definition

VCC: brown, GND: black, 485A: green, 485B: blue

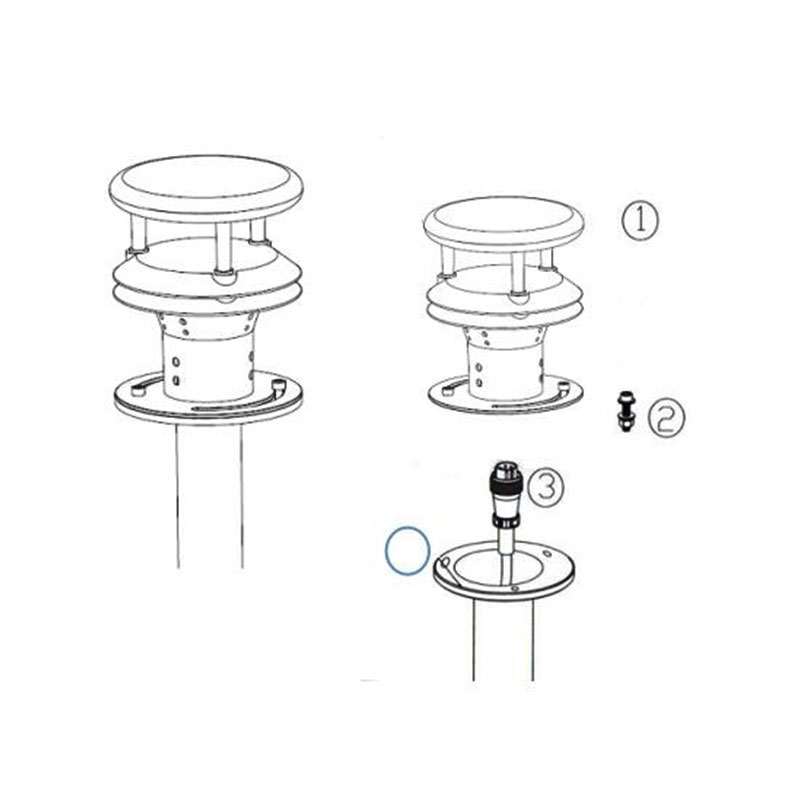

7. Explosion Proof Sensor flange fixing method

1. Micro-weather instrument

2. Fixing screws

3. Communication cable + aviation plug

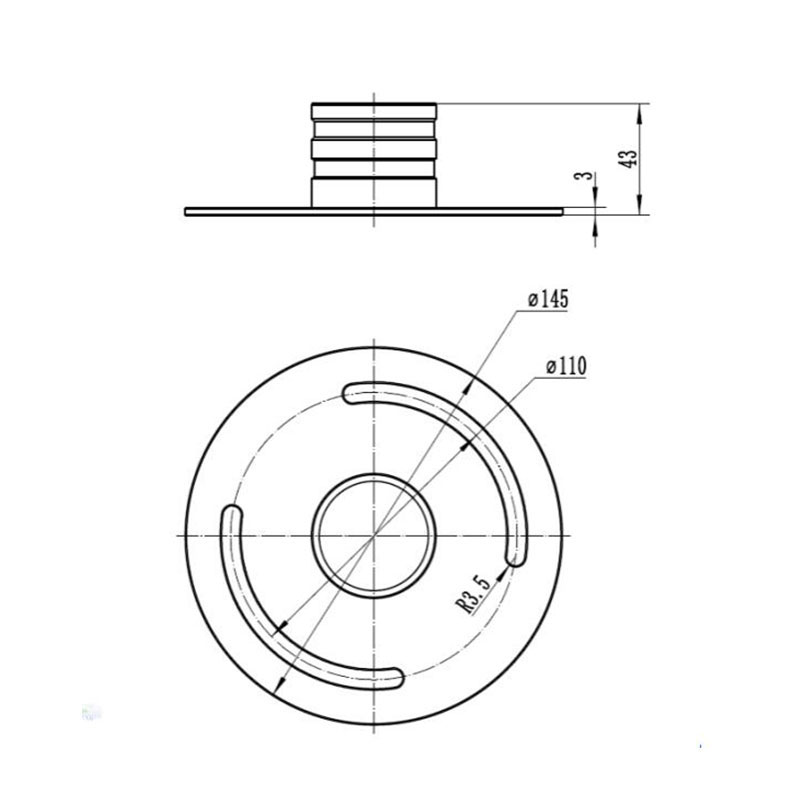

8. Explosion Proof Sensor Flange Size

Related article

-

Scenic anion monitors are a highlight of scenic publicity!

2024-03-26 -

Dust Detector and Mobile Monitoring in Air Quality Protection

2025-01-06 -

How Miniature Sensors Aid in Accurate Fertilization for Tea Gardens

2024-10-18 -

Forest Weather Monitoring System to protect against hill fires

2024-04-29 -

Meteorological Observation Station: Unraveling the Mysteries of Weather

2024-09-20 -

Road Weather Information System: Enhancing Road Safety and Efficiency

2024-09-27 -

Vehicle-Mount Weather Station in Action: Tackling Meteorological Disasters Head-On

2024-12-05 -

Road Weather Information System: Tackling the Challenge of Dense Fog Patches

2024-09-30

Get a Free Quote

Get a Free Quote